Battery Test Center

The TU Clausthal operates a Battery and Sensor Test Center (https://www.batteriesicherheit.eu/batterie-und-sensoriktestzentrum) with the Research Center Energy Storage Technologies and the Fraunhofer Heinrich Hertz Institute at the Battery Safety Campus Germany. This combines a research infrastructure for testing of high- performance battery systems which is unique nationwide in terms of performance. With this infrastructure, the partners are prepared for future challenges, when batteries for buses and trucks are nothing out of the ordinary and even charging of these 500 kW batteries is not uncommon any more.

Battery tests in limit ranges

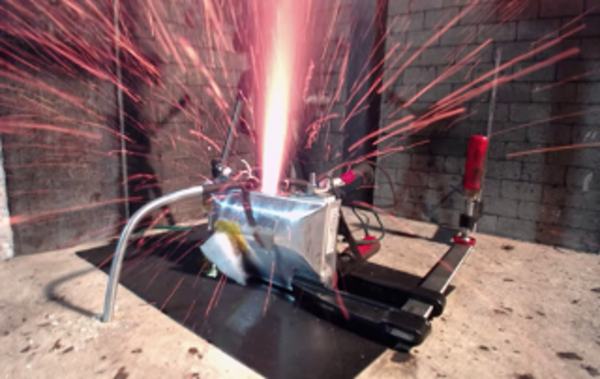

The experiments in limit ranges for Li-ion batteries are, for example, short-circuit and overload experiments. Short-circuit tests produce disproportionately high currents and increased heating. Security mechanisms or thermal propagation within a module or even entire battery systems are of particular interest here. Overcharged batteries show a much more reactive behavior and are therefore regarded as an unmistakably high source of danger. In the case of an unwanted fire of a Li-ion battery, the spread of fire is particularly important and should be kept under control and analyzed.

Investigation of the extinguishing effect of various extinguishing agents and the fire behavior of lithium-ion batteries

Lithium-ion batteries are now one of the most important electrochemical storage technologies in the commercial sector. They are used in a variety of portable devices, for electric cars, home storage systems and many other applications around the clock. They are particularly important mainly because of their high energy density. However, the question in everyday use is, what happens in the event of a battery fire and what requirements are made of a possible extinguishing agent. That is the challenge for manufacturers of extinguishing agents, because battery fires cannot be compared with traditional house fires. The requirements are versatile and require a high level of know-how in research and development.

Together with the company FNL Neuruppin and the researchers of the TU Clausthal, experimental proof of the extinguishing effect of various extinguishing agents in fires of lithium-ion batteries is provided. At the Germany Battery Safety Campus, innovative concepts for the prevention of battery fires can be developed and the effectiveness of extinguishing agents for different storage technologies can be investigated.

Abuse tests of lithium-ion cells

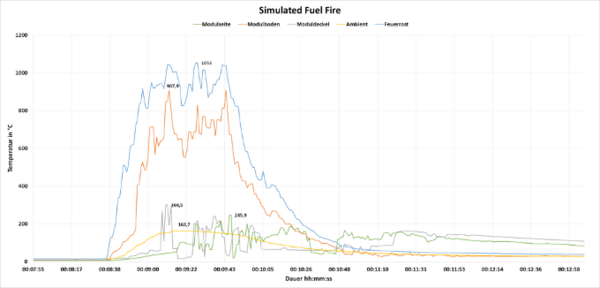

The available infrastructure allows us to test batteries not only up to the load limit, but also beyond it, through existing fire furnaces. In addition to the simulation of critical situations, targeted abuse tests according to standards are also possible. Fig. 3 illustrates the temperature curve of a battery in a so-called fuel fire test according to ECE R100. Here, it is simulated how a lithium-ion vehicle battery reacts to a gasoline fire, e.g. after an accident.

Performance testing and safety measures for high-performance lithium-ion batteries

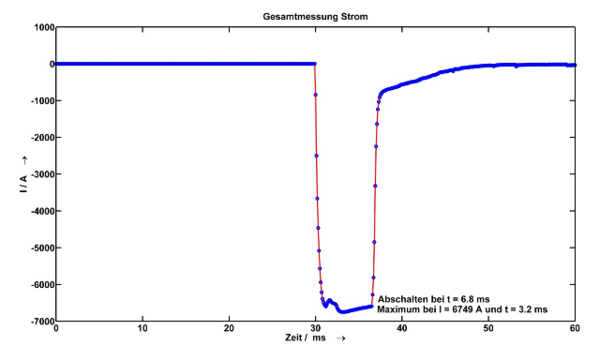

As part of the safety review of batteries and battery systems, tests are carried out in accordance with various standards in the battery test center. Examples include different tests from the regulations ECE R100, ECE R136 and UN T 38.3 and various ICE standards. Such regulations define the thermal, electrical and mechanical requirements for the respective battery systems and stipulate test procedures for them. All required test sequences from the thermal and electrical field can be realized in the battery test center. The following figure shows the current curve for a short-circuit test according to ECE R100. The high-voltage battery storage system has a rated voltage of 552 volts and an energy content of 88 kWh.

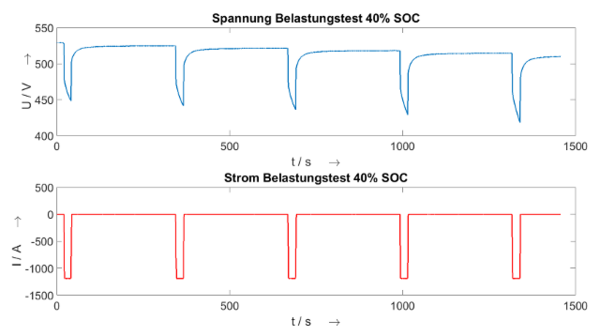

Performance tests can be done up to a maximum power of 1.2 MW. In this way, requirements arising from a particular application can be checked at system level. Furthermore, the existing test facilities are suitable for determining charging factors and efficiencies of complete systems. In the following, the voltage for the above-mentioned system is shown as a function of short loads which are characteristic for an operation of the system.